In today's fast-paced logistics environment, mastering Less Than Truckload Shipping is crucial for businesses. Many companies rely on this method to cut costs and increase efficiency. However, achieving success can be challenging. It's essential to navigate its complexities with care.

One key element is understanding various carriers and their services. Not all carriers offer the same rates or reliability. Researching and comparing options can lead to better decisions. Late deliveries and damaged goods pose significant risks. Attention to detail in packaging can prevent these issues.

Additionally, clear communication with carriers and shippers is vital. Misunderstandings can lead to delays and extra costs. Companies often overlook the importance of tracking shipments effectively. This oversight can diminish customer satisfaction. Reflecting on these aspects of Less Than Truckload Shipping can help avoid pitfalls and enhance overall performance.

Less Than Truckload (LTL) shipping is a cost-effective option for businesses that don’t have enough freight to fill an entire truck. It involves consolidating multiple shipments from different sources into one truck. This method can save money but requires careful planning. The right strategies can enhance the shipping experience.

Start by understanding size and weight restrictions for LTL. It's crucial to know how your freight will be categorized. Accurate measurements prevent unexpected charges. Always provide detailed descriptions of your cargo. Miscommunication can lead to delays and additional fees. Keep your shipping documents organized.

Consider the timing of your shipments. Picking non-peak times can lead to better rates and faster deliveries. Also, build strong relationships with carriers. Trust can lead to better service and more flexible terms. But even the best plans can go awry. Sometimes, delays or damage happen. Reflecting on these issues helps in improving future shipments. Efficient LTL shipping is a learning process.

Choosing the right carrier for less than truckload (LTL) shipping is crucial. Every shipment matters. An inefficient choice can lead to delays. Look for carriers that offer flexible delivery options. Not all carriers have the same reliability. Some may promise fast service but fail to deliver. Research is key.

Consider the carrier’s reputation in your industry. Do they have experience with your type of freight? Ask for reviews or references. It’s helpful to learn from others’ experiences. Cost is another factor, but it shouldn’t be the only one. Cheap rates can sometimes mean subpar service.

Evaluate the carrier's tracking technology too. Real-time updates provide peace of mind. If they lack this feature, think twice. Communication is vital. A carrier who doesn’t keep you informed can lead to frustration. Look for one that prioritizes customer service. Your choice can make or break your shipping efficiency. Reflect on what works for you and adjust as needed.

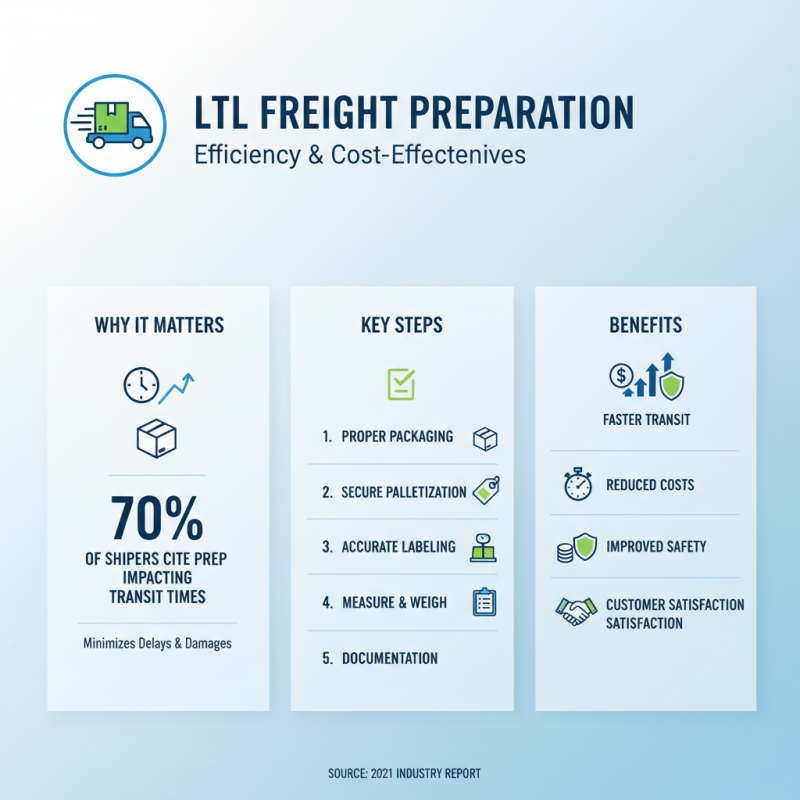

Preparing your freight for less than truckload (LTL) shipping is crucial for ensuring efficiency and cost-effectiveness. According to a 2021 industry report, nearly 70% of shippers identified freight preparation as a significant factor impacting transit times. Properly packing and labeling your freight minimizes the risk of delays and damages.

Use strong materials for packaging. This includes durable boxes and protective padding. Inadequate packaging can lead to 20% more damages during transit. Also, consider the weight distribution within the shipment. Uneven weight can cause loading issues and prolong transit times. Aim to keep the weight centered and secure.

Labeling is equally important. Missing or unclear labels can confuse freight handlers, resulting in rerouting or misdelivery. In fact, a study found that 33% of delays are due to improper labeling. Double-check all documentation for accuracy. Small mistakes can lead to significant setbacks, costing time and money. Focusing on these key areas can help enhance your LTL shipping success.

Less than Truckload (LTL) shipping can be cost-effective, but managing costs requires careful planning. Start by understanding your shipment's dimensions and weight. Accurate measurements prevent unexpected charges. Many shippers underestimate these details, which can lead to higher expenses than anticipated. Use a reliable calculator to avoid costly errors.

Think about zoning and distance too. Shipping rates can vary widely based on your location. Rural areas often incur higher fees. If you frequently ship to the same destinations, negotiating contracts could be beneficial. Consider consolidating shipments to maximize space. Combining smaller freight can lead to better pricing opportunities.

Don’t ignore accessorial charges. These costs accumulate quickly and can include liftgate service or inside delivery. Being aware of potential fees can help maintain budget control. Review invoices carefully. Mistakes happen. If you find discrepancies, address them immediately. Tracking these details can lead to better decisions in future shipments.

Effective tracking and communication are vital in LTL shipping. They ensure timely deliveries and minimize disruptions. Start by choosing a reliable tracking system. This will provide real-time updates on shipment status. Many systems allow you to set alerts for key milestones. This keeps everyone in the loop.

Regular communication with all parties is essential. Keep lines open between shippers, carriers, and customers. Share updates regularly. A simple text or email can prevent confusion. A lack of communication can lead to delays and frustrations. Encourage feedback from your team. It often reveals gaps in the current process. Understanding these gaps can lead to improvements.

Consider the impact of unexpected changes. Weather, road closures, and equipment failures can disrupt schedules. Have a contingency plan ready. Discuss potential obstacles with your team and carriers. Brainstorm possible solutions before problems arise. This proactive approach creates a culture of accountability and preparedness. Clear communication can turn challenges into manageable tasks.